Dentcore

hyperDENT Implant Light Bundle

Share

FOLLOW-ME! – hyperDENT®

hyperDENT® is the world leading software system in the dental CAM market and is valued among experts for its modular product structure. Our customers are provided with CAM solutions tailored to their specific application and implementation needs. Regardless of company size and whether for dental or practice labs, FOLLOW-ME! offers suitable hyperDENT® product bundles for a perfect interaction between CAM and machines.

hyperDENT® Overview

→ Open, highly automated and flexible system

→ Complete production process coverage with a single CAM software

→ Simple, intuitive operation

→ Maximum precision and time efficiency throughout the entire process

→ Material-independent

→ Flexible addition of software modules

→ Maximum freedom in creating templates

→ Additive manufacturing and milling all-in-one

→ Automatic material offset for post milling during the hybrid process

→ Automatic part identification using ID tags

→ Optimum surface finish quality due to proven tool path calculation

→ Consistent software enhancement and development

→ Worldwide premium support service

hyperDENT® Product Overview

REQUEST A QUOTE-

hyperDENT® Classic

Advanced open CAM solution ideal for milling centers and dental labs, offering flexibility, efficiency, and customization. Its key features include simultaneous project processing, customizable milling strategies, and machine automation interfaces, along with a specialized Implant Module. This software meets demanding market needs and enhances customer satisfaction, positioning it as a high-performance tool for professional users.

-

hyperDENT® Compact

Designed for use in dental labs and can be utilized on all open milling machines. The simplified user interface with a managed workflow provides real added value for high-end newcomers and those who wish to become quickly familiar with CAM. Provided databases allow fast, secure, efficient and precise milling. With the exception of one-piece abutments and bridge constructions, all indications can be manufactured using hyperDENT® Compact.

-

hyperDENT®Practicelab

Geared to the needs of practice labs and is optimally suited for CAM newcomers. The user interface is highly automated, which facilitates handling significantly. The managed workflow and minimized range of functions enable the user to calculate tool paths for individual blanks, such as glass ceramic blocks and preform abutments, in just a few steps and send them to the machine for milling.

-

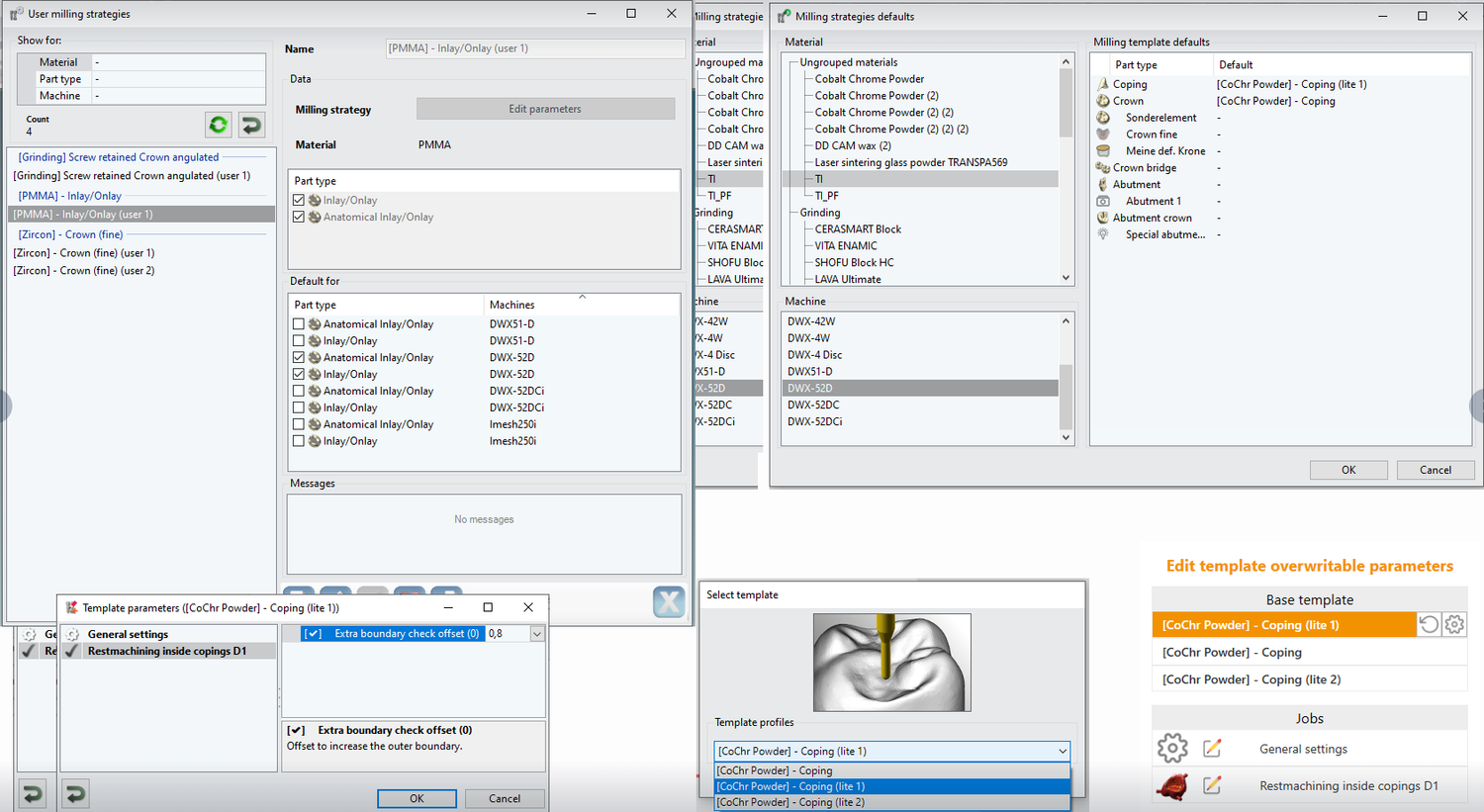

hyperDENT® Options

Additional modules can be added to hyperDENT® Compact as well as hyperDENT® Classic licenses enabling the CAM software to perfectly match user requirements. Individual modules can be added easily at any time.

The following modules are available:

→ hyperDENT® Template Generator Module

→ hyperDENT® Hybrid Module

→ hyperDENT® Implant Module

→ hyperDENT® Denture Module

Auto part list

hyperDENT® can be directly connected to the output file of the CAD system thereby enabling the CAM to automatically recognize new designs and include them in the part list for further machining and management.

C clamp function

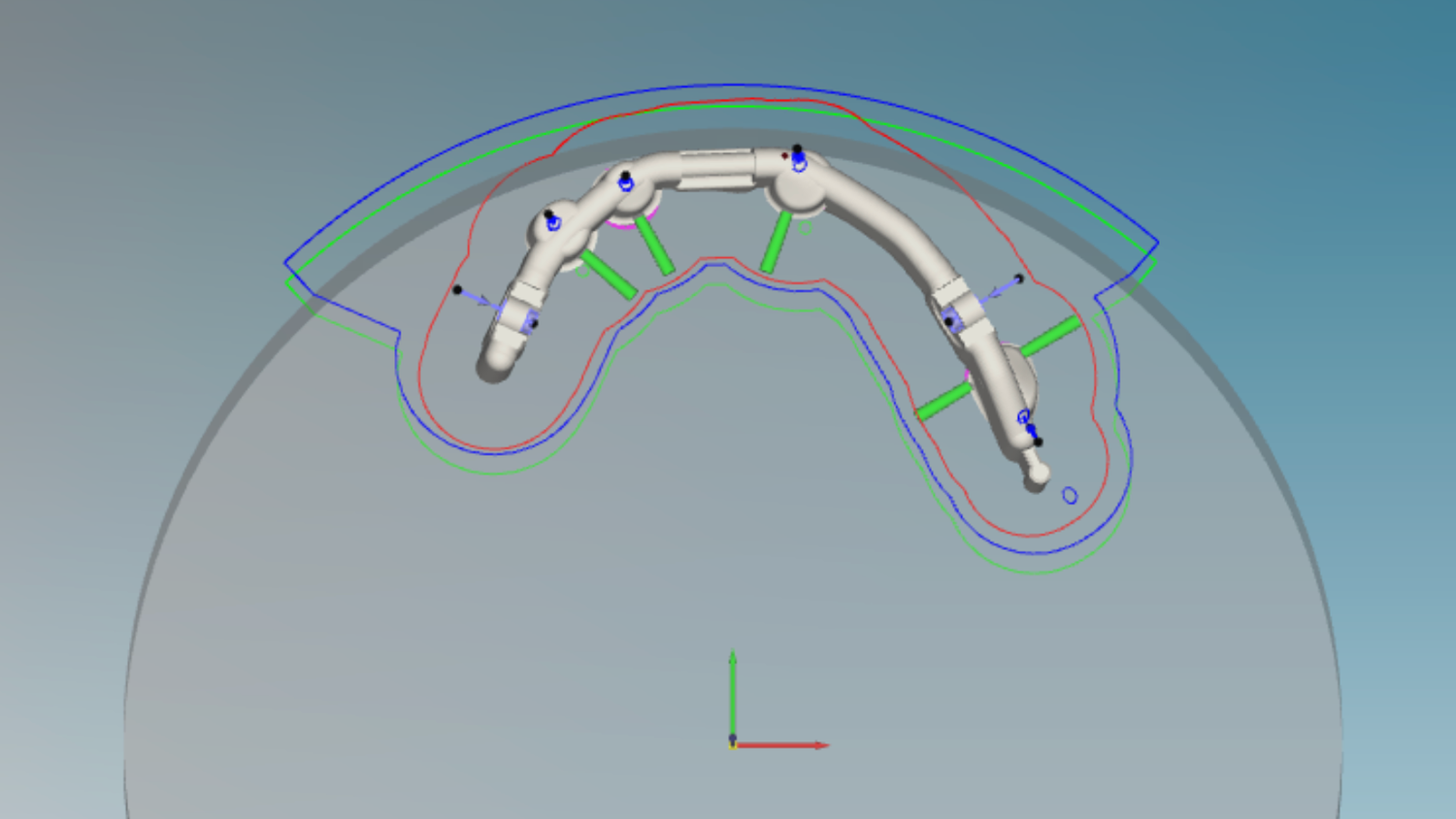

hyperDENT® supports clamping devices which allow horizontal processing of dental parts (C clamp). Utlization of lateral drilling and lateral details can now be fully automated.

Milling of implants and geometries

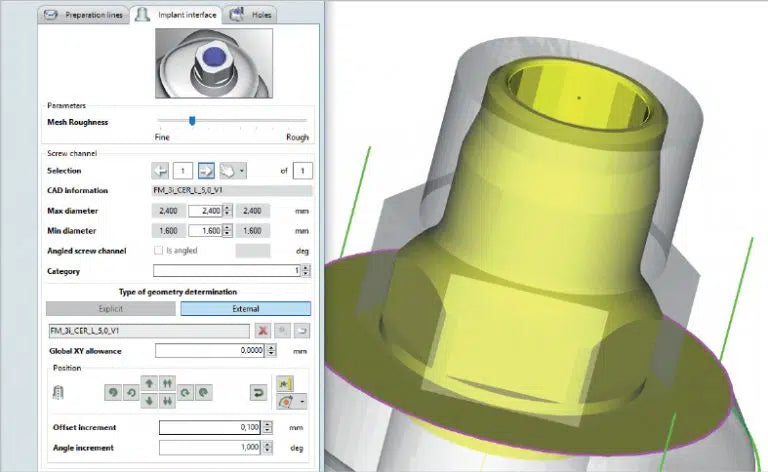

With the hyperDENT® Implant Module, customized abutments, implant bridges and bars can be manufactured from circular blanks. Due to intelligent categorization, only one master template is required for all systems. This module can also be combined

with a millable interface geometry library for the most commonly-used implant systems. This library can be linked to a corresponding CAD dummy geometry library. It is easy to implement your own geometries as well. Despite possible inaccuracies in upstream systems, an automated exchange mechanism for geometries ensures that high precision parts are

manufactured.

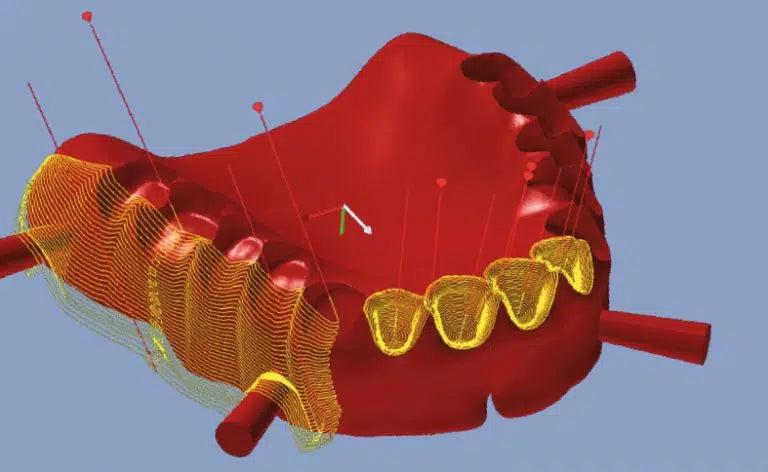

Manufacturing of full dentures

The hyperDENT®Denture Module enables digital manufacturing of full dentures with a significantly reduced processing time compared to the analog process. hyperDENT® is one of the first CAM software systems to provide a specified and automated tool paths for this indication type. With the Denture Module, you can produce different workflow variations such as fully completed rows of teeth or pre-milled tooth pockets. Interfaces to diverse CAD systems are available and guarantee easy handling.

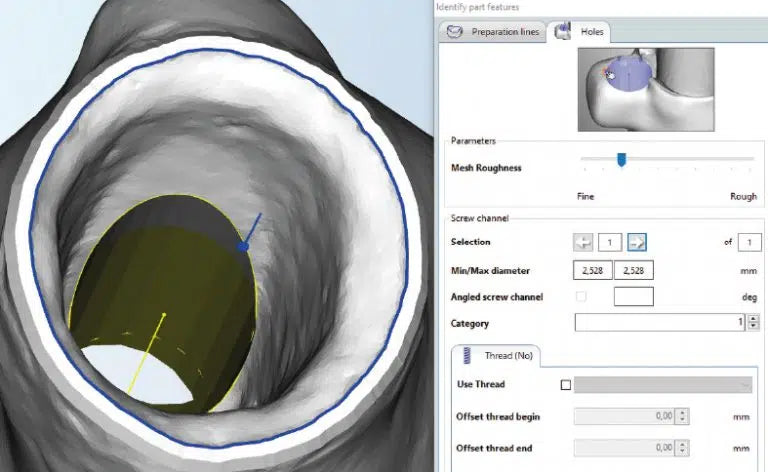

Cavity milling

The milling of cavities/holes is required repeatedly and hyperDENT® is capable of milling these milling these with all part types. Through categorization, different requirements can be managed easily, even for the same part.